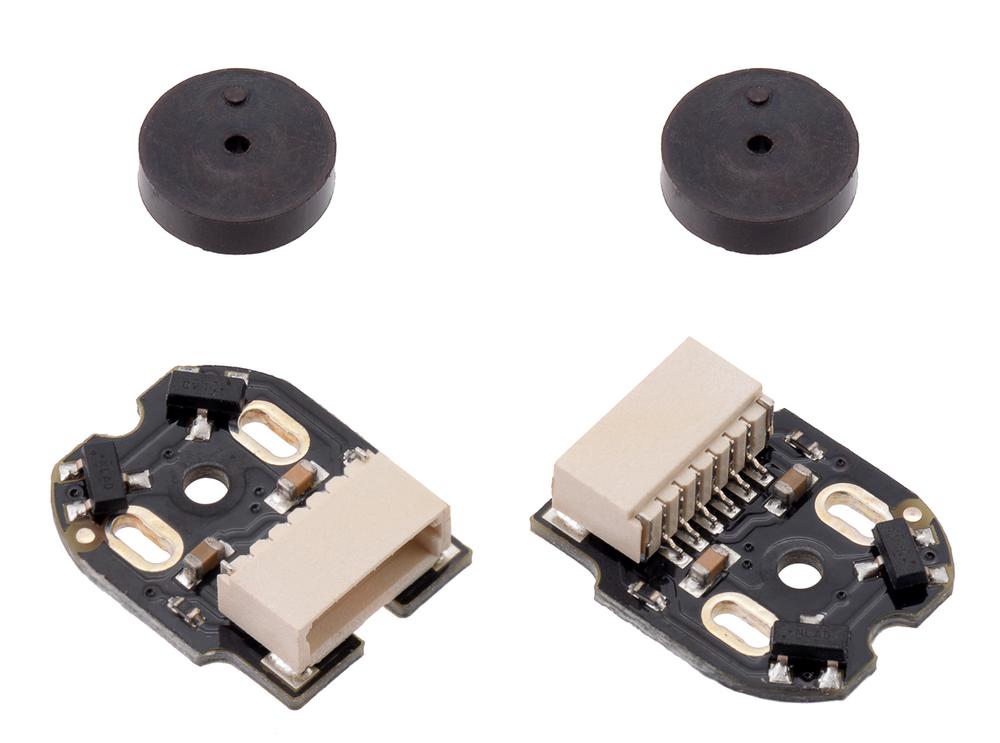

Pololu Magnetic Encoder Pair Kit with Side-Entry Connector for Micro Metal Gearmotors, 12 CPR, 2.7-18V

Description Attachments

Magnetic Encoder Pair Kit with Side-Entry Connector for Micro Metal Gearmotors, 12 CPR, 2.7-18V. Add quadrature encoders to your micro metal gearmotors (extended back shaft version required) with this kit that uses a magnetic disc and hall effect sensors to provide 12 counts per revolution of the motor shaft. The sensors operate from 2.7 V to 18 V and provide digital outputs that can be connected directly to a microcontroller or other digital circuit. These encoders have a side-entry, 6-pin male JST SH-type connector, and we have cables that work with them available in several lengths (12 cm, 30 cm, and 75 cm). This module is compatible with all of the dual-shaft micro metal gearmotors we carry, including the HPCB versions.This kit includes two dual-channel Hall Effect sensor boards and two 6-pole magnetic discs that can be used to add quadrature encoding to two micro metal gearmotors with extended back shafts (motors and cables are not included with this kit). The encoder board senses the rotation of the magnetic disc and provides a resolution of 12 counts per revolution of the motor shaft when counting both edges of both channels. To compute the counts per revolution of the gearbox output shaft, multiply the gear ratio by 12. This compact encoder solution fits within the 12 mm × 10 mm cross section of the motors on three of the four sides, and it extends 4.2 mm past the edge of the fourth side.The encoder board is designed to be soldered directly to the back of the motor, with the back shaft of the motor protruding through the hole in the middle of the circuit board. One way to achieve good alignment between the board and the motor is to tack down the board to one motor pin and to solder the other pin only when the board is flat and well aligned. Be careful to avoid prolonged heating of the motor pins, which could deform the plastic end cap of the motor or the motor brushes.

Properties

Brand information

| Brand | Pololu |

| Model | 4761 |

€ 10,05€ 8,30 Excl. VAT (NL)

+ + =

Frequently bought together Total price:

Alternative products

- Pololu Magnetic Encoder Pair Kit for Micro Metal Gearmotors, 12 CPR, 2.7-18V (HPCB compatible) € 11,15 View product

- In stock Pololu Magnetic Encoder Pair Kit with Top-Entry Connector for Micro Metal Gearmotors, 12 CPR, 2.7-18V € 10,05 View product

- 2 pieces Pololu Optical Encoder set for Micro Metal Gear motors, 5V - 2 pcs € 16,75 View product

- 2 pieces Pololu Optical Encoder set for Micro Metal Gear motors, 3.3V - 2 pcs € 16,75 View product

Related products

- Pololu 6-Pin Female-Female JST SH-Style Cable 63cm € 6,70 View product

- Pololu 6-Pin Female-Female JST SH-Style Cable 40cm € 5,40 View product

- Pololu 6-Pin Female-Female JST SH-Style Cable 16cm € 4,05 View product

- Pololu 6-Pin Female-Female JST SH-Style Cable 10cm € 3,75 View product

- Pololu 6-Pin Female-Female JST SH-Style Cable 25cm € 4,55 View product

Customer questions

Q

Customer Reviews

Pololu Magnetic Encoder Pair Kit with Side-Entry Connector for Micro Metal Gearmotors, 12 CPR, 2.7-18V ★★★★★Click a star to leave your review

- In stock Pololu 3.3V Step-Up Voltage Regulator U1V11F3 € 8,90 View product

- In stock Pololu Ball Caster with 3/8″ Metal Ball € 3,30 View product

- Deal In stock -15 % Pololu 5V, 1A Step-Down Voltage Regulator D24V10F5 € 14,50 € 12,30 View product

- In stock Pololu Step-Up/Step-Down Voltage Regulator S7V7F5 € 9,50 View product

- In stock Pololu 5V, 3.4A Step-Down Voltage Regulator D30V30F5 € 22,35 View product

- In stock Pololu 5V, 500mA Step-Down Voltage Regulator D24V5F5 € 10,05 View product

- In stock Pololu 3.3V Step-Up Voltage Regulator U1V10F3 € 7,80 View product

- In stock Pololu 9V, 600mA Step-Down Voltage Regulator D24V6F9 € 12,30 View product

- In stock Pololu 3.3V, 2.6A Step-Down Voltage Regulator D24V22F3 € 21,25 View product

- In stock Pololu Snap-Action Switch with 16.3mm Roller Lever: 3-Pin, SPDT, 5A € 2,85 View product

- In stock Pololu 9mm Electromagnetic Buzzer: 40Ω, 4-6V, Top Opening € 2,20 View product

- In stock Pololu Stranded Wire: Black, 30 AWG, 100 Feet € 11,15 View product

- Sale In stock -73 % Pololu 7.5V, 600mA Step-Down Voltage Regulator D36V6F7 € 18,15 € 4,85 View product

- In stock Pololu 5V, 3.2A Step-Down Voltage Regulator D36V28F5 € 24,60 View product

- In stock Pololu Stranded Wire: White, 20 AWG, 40 Feet € 13,40 View product