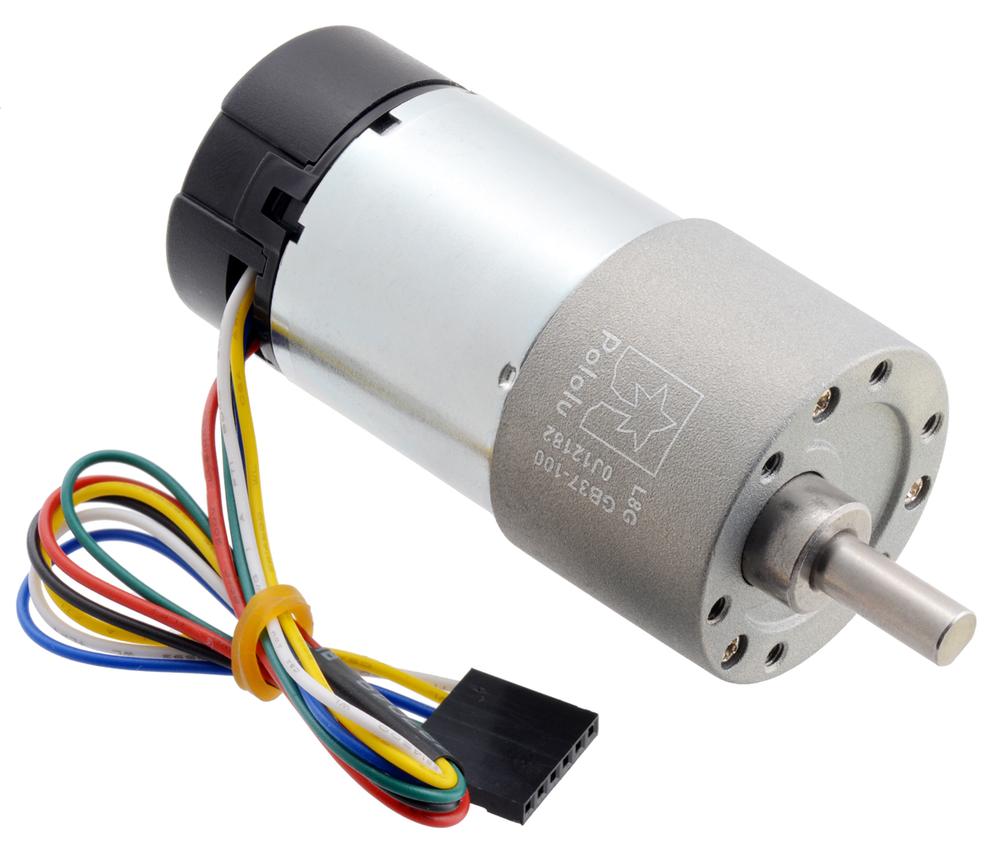

Pololu 100:1 Metal Gearmotor 37Dx73L mm 24V with 64 CPR Encoder (Helical Pinion)

Description

The 100:1 Metal Gearmotor 37Dx73L mm 24V with 64 CPR Encoder (Helical Pinion) is a robust gearmotor that combines a powerful 24V brushed DC motor with a 102.08:1 metal gearbox. It features an integrated quadrature encoder that provides a resolution of 64 counts per revolution of the motor shaft. This equates to an impressive 6533 counts per revolution of the gearbox's output shaft. The gearbox is primarily made of spur gears, but it utilizes helical gears for the first stage to minimize noise and enhance efficiency. The gearmotor comes with a 16 mm long, 6 mm diameter D-shaped output shaft. An alternative model without an encoder is also available for purchase.The gearmotor is ideal for projects that require high precision and control. The integrated quadrature encoder makes it perfect for applications that require accurate positioning and speed control. With its high resolution, it can be used in robotics for precise movements, in conveyor systems for exact positioning, or in any application where precision and control are paramount.The gearmotor is distinguished by its high power and efficiency. The 24V brushed DC motor delivers robust performance, while the 102.08:1 metal gearbox ensures optimal efficiency. The first stage helical gears contribute to noise reduction, making the gearmotor a quiet solution for noise-sensitive applications. The D-shaped output shaft, with a length of 16 mm and a diameter of 6 mm, ensures easy and secure coupling.Key specifications include a voltage of 24V, no-load performance of 100 RPM at 100 mA, and stall extrapolation of 39 kg⋅cm (540 oz⋅in) at 3 A. These specifications make the gearmotor a reliable and powerful choice for a wide range of applications.

Properties

Brand information

| Brand | Pololu |

| Model | 4695 |

€ 67,30€ 55,60 Excl. VAT (NL)

Delivered in 5 to 14 days

Customer questions

Q

Customer Reviews

Pololu 100:1 Metal Gearmotor 37Dx73L mm 24V with 64 CPR Encoder (Helical Pinion) ★★★★★Click a star to leave your review

- In stock Pololu 3.3V Step-Up Voltage Regulator U1V11F3 € 8,75 View product

- In stock Pololu Step-Up/Step-Down Voltage Regulator S7V7F5 € 9,35 View product

- In stock Pololu 5V, 3.4A Step-Down Voltage Regulator D30V30F5 € 22,- View product

- In stock Pololu Logic Level Shifter, 4-Channel, Bidirectional € 3,85 View product

- In stock Pololu 3.3V, 2.6A Step-Down Voltage Regulator D24V22F3 € 20,90 View product

- In stock Pololu 9V, 600mA Step-Down Voltage Regulator D24V6F9 € 12,10 View product

- 100 pieces In stock Pololu Female Crimp Pins for 0.1" Housings 100-Pack € 13,20 View product

- 100 pieces In stock Pololu Male Crimp Pins for 0.1" Housings 100-Pack € 19,80 View product

- In stock Pololu 9mm Electromagnetic Buzzer: 40Ω, 4-6V, Top Opening € 2,15 View product

- In stock Pololu Stranded Wire: Black, 30 AWG, 100 Feet € 11,- View product

- Sale In stock -73 % Pololu 7.5V, 600mA Step-Down Voltage Regulator D36V6F7 € 18,15 € 4,85 View product

- In stock Pololu 5V, 3.2A Step-Down Voltage Regulator D36V28F5 € 24,20 View product

- In stock Pololu Stranded Wire: White, 20 AWG, 40 Feet € 13,20 View product

- In stock Pololu 5V Step-Up/Step-Down Voltage Regulator S8V9F5 € 11,- View product

- In stock Pololu 5V Step-Up Voltage Regulator U1V10F5 € 7,70 View product